ED conditioning

EPICS routine for conditioning ED1, ED2 at high voltage

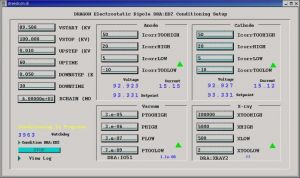

High voltage conditioning of the DRAGON electrostatic dipoles may be achieved using the EPICS routine "Condition DRA:ED1/2." The conditioning routine monitors properties of the dipole effected by the conditioning (the tank pressure, the x-ray rate, the anode current, and the cathode currents), and allows for a slow conditioning of the EDs under computer control. To find out why conditioning may be necessary, please consult the [Separator Hardware User's Manual](sep_hardware.html#2).

The routine may be initialized from the EPICS page "Optics|Condition ED1", accessible from the DRAGON menu bar. This page allows for initialization, monitoring, and termination of the HV conditioning.

HV Conditioning Algorithm

Each of the four monitored parameters (anode current, cathode current, pressure, and x-rays) must be between 2 numbers ("Too Low" and "Low") before a voltage increase will take place. Such an upward step in voltage (an increase of "Upstep" kV) will only be considered by the control loop once every "Uptime" seconds.

The need to step voltage back down because of increased activity in any of the four monitored parameters is considered once every "Downtime" seconds. �The HV setpoint will be reduced by "Downstep" kV if any of the four parameters lies in the range between "High" and "Too High".

Parameters lying between "Low" and "High" are neither a cause for a down-step nor license for an up-step in HV. �Instead, the control loop will sit at the same voltage setpoint until another "Uptime" or "Downtime" seconds have elapsed.

If any parameter is found to be higher than "Too High", the routine exits from the control loop on the assumption that something has gone wrong with a readback, or some other unexpected hardware failure has happened. �Similarly, the control loop will terminate if any parameter is found to be "Too Low."

Conditioning can also be terminated if the user clicks the Stop button on the conditioning page, or if some other agent (user or Scaling routine) changes the Setpoint value from the value last set by the HV Conditioner.

To set up HV Conditioner

1. Manually determine the HV Setpoint at which signs of conditioning appear and enter this number as VSTART (in kV). \[[Consult figure below](#picture)\]

2. Enter the voltage at which conditioning should end as VSTOP (in kV).

3. Enter the step size for voltage increases as UPSTEP (in kV). � Suggested: 0.01

4. Enter the minimum interval between steps up as UPTIME (in seconds). Suggested: 120

5. Enter step size and interval for voltage decreases as DOWNSTEP and DOWNTIME, respectively. Suggested: 0.05 kV and 30 sec

6. Specify the effective resistance of the HV stack (MOhms = V/uA) as RCHAIN. �(We are interested in the net current after stack current is subtracted.) �Suggested: 6000

7. Specify the TOOLOW, LOW, HIGH, and TOOHIGH limits of anode current and cathode current (uAmps). �Suggested: -10, 5, 20, 50

8. Specify the limits on pressure (in Torr). ��Suggested: 0.7E-9, 5.0E-7, 3.0E-6, 3.0E-5

9. Specify the x-ray rates. �Suggested:

ED1: 2, 300, 5000, 300000ED2: 2, 3000, 10000, 300000

Start the conditioning by clicking on the "Condition DRA:ED1" (or :ED2) button at the bottom left corner of the page. A watchdog timer should start counting up from 0 and keep counting as long as the control loop has not been terminated. �The read-back voltages and currents as well as the most recent setpoint voltage are displayed in the Anode and Cathode boxes.

In each of the four boxes a green triangle will point up if everything is OK to step up the HV, or will point down if the HV should be stepped down. �If the control loop is terminated because one parameter remained out-of-range, a red "stop sign" is displayed for that parameter. �The value which caused abnormal termination should appear in the last part of the log file, which can be displayed by clicking on the "View log" button at the bottom left corner of the page.

Dave Hutcheon 26 Feb 2003